The Austrian Automobile, Motorcycle and Touring Club ÖAMTC wanted to concentrate its Vienna offices in one building and establishes new headquarters with office area, support functions, membership service and a heliport. The location directly at a highly frequented motorway reflects the mission of ÖAMTC. Its unique, circular and star-shaped form emphatically conveys the fact that here everything revolves around mobility and at the same time demonstrates the efficiency and speed of the organisation.

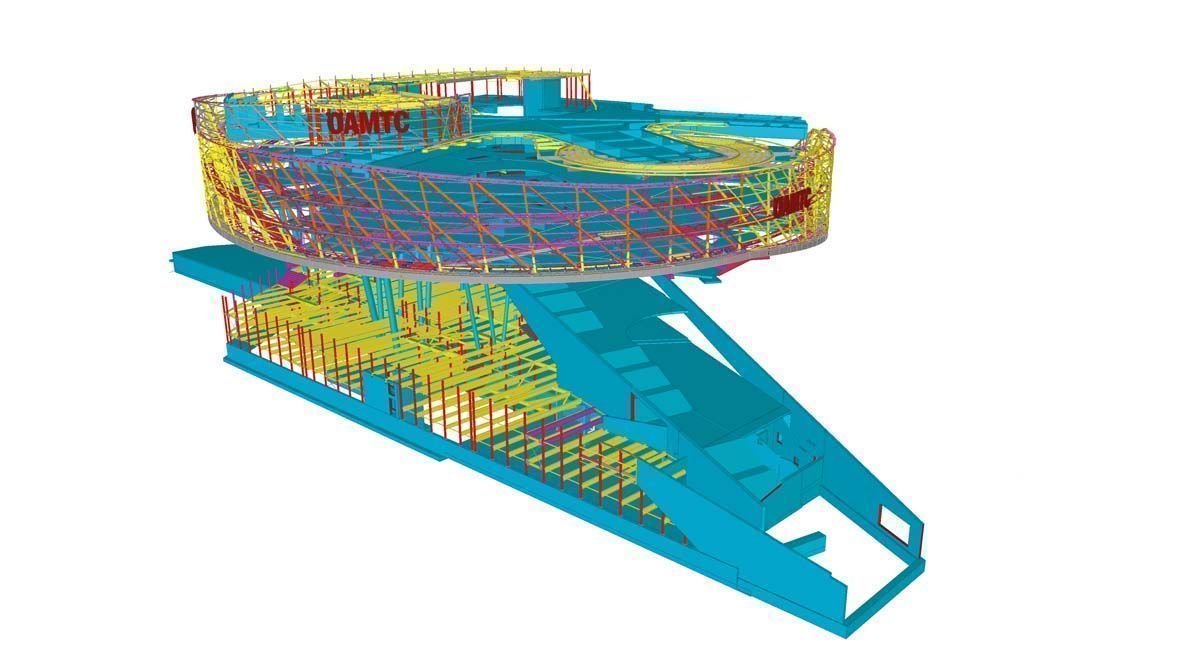

The building has the form of a rim with five spokes. The 230 m long and nearly 17 m high ring facade forms the connecting element that extends from spoke to spoke. Architects, structural engineers and building contractors cooperated in the implementation of the prominently positioned steel-glass construction of the ring facade during the planning phase, relying on Building Information Modeling technologies. The ring facade is arranged in five layers from the outside to the inside, projecting up to 35 m from the building.

Forces due to restrained thermal expansion of the ring façade may not be transferred to the reinforced concrete structure. This was solved by a continuous ring façade without expansion joint but decoupled direction with elastomeric bearings. The circumferential main supporting element is a lower welded box girder. The diagonals are stretching from the box girder to the top lattice girder, which transfers wind loads to the concrete structure.

The structural analysis of the complex structure was done on a spatial, geometrically linear model. Second-order effects were neglected. The stiffening tension rods of the post-and-mullion structure were not allowed to fail with added loads. The glazing is directly connected to the steel structure and hence the allowable tolerances are low such that minimal and accurate deformations had to be determined. Critical deformations were essentially determined by characteristic loads as well as wind effects. A model was tested in a wind tunnel in 24 directions in 15° steps with ca. 150 pressure measuring points inside and outside of the ring facade. With the suction and pressure distributions available, it was possible to optimally design the structure section by section.

The assembly of the ring facade was divided into five construction phases to be able to meet the specially developed assembly concept and comply with the deadlines for subsequent works. The building sections were lifted to the height of the installation area using a 130 to crane and a 250 to crane in a tandem lift. The super elevation of the concrete structure had to be considered with the required mounting towers for the box girder. Jacks were used at the steel structure’s support points. The assembly concept is designed that an office spoke can be added in a potential second building phase.

| Project owner | Austrian Automobile, Motorcycle and Touring Club | |

|---|---|---|

| Location | Baumgasse 129, Vienna, AT | |

| Architect | Pichler & Traupmann Architekten Vienna | Johanna Maria Priebe |

| Structural Engineer | Ebner ZT Innsbruck FCP Fritsch, Chiari & Partner ZT Vienna Unger Stahlbau Oberwart | Dieter Ebner Wolf-Dietrich Denk Bernd Mühl |

| Steel Contractor | Unger Stahlbau Oberwart | Bernd Mühl |

| Date of Completion | March 2017 | |

| Steel Tonnage | 2,000 tons |