01. April 2020

Journal Geomechanics and Tunnelling 2/2020 published

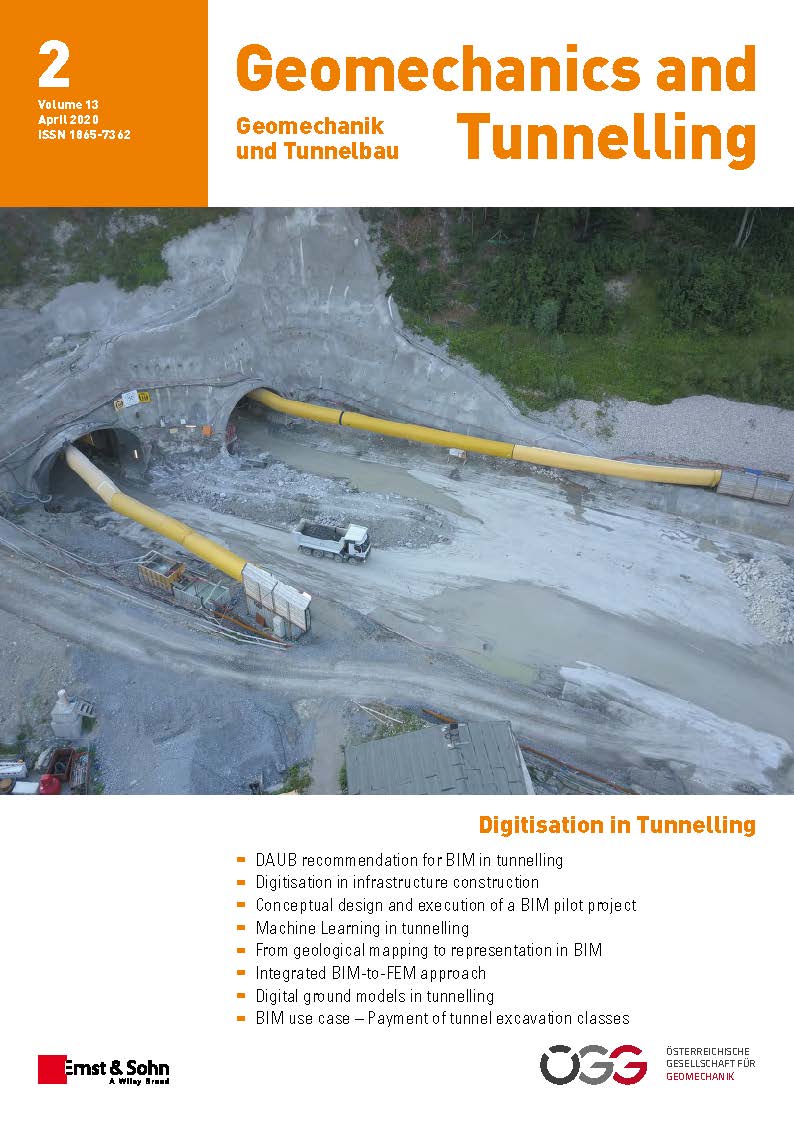

Cover picture:

The 2.9 Tm long twin-tube Oberau Tunnel is the central element of the 4.2 km long Oberau bypass. 80 % of the tunnel was excavated by drill and blast in hard rock and 20 % by hydraulic excavator in the soil crossing the Gießenbach valley. In the soft ground section, which is susceptible to settlement, the works were carried out under the protection of pre-support in the form of an umbrella of AT-Tubespiles with lengths of 6 m.

The 2.9 Tm long twin-tube Oberau Tunnel is the central element of the 4.2 km long Oberau bypass. 80 % of the tunnel was excavated by drill and blast in hard rock and 20 % by hydraulic excavator in the soil crossing the Gießenbach valley. In the soft ground section, which is susceptible to settlement, the works were carried out under the protection of pre-support in the form of an umbrella of AT-Tubespiles with lengths of 6 m.

Table of Contents Journal Geomechanics and Tunnelling 2/2020

- DAUB recommendation for BIM in tunnelling

- Digitisation in infrastructure construction

- Conceptual design and execution of a BIM pilot project

- Machine Learning in tunnelling

- From geological mapping to representation in BIM

- Integrated BIM-to-FEM approach

- Digital ground models in tunnelling

- BIM use case – Payment of tunnel excavation classes

Recommendations

- Winter, Stefan / Peter, Mandy (eds.)

Holzbau-TaschenbuchGrundlagen

10. Edition – August 2021- XIV, 546 pages

- Hardcover

- German

ISBN: 978-3-433-01805-7available- €99,00

- de Borst, René / Crisfield, Mike A. / Remmers, Joris J. C. / Verhoosel, Clemens V.

Nichtlineare Finite-Elemente-Analyse von Festkörpern und Strukturen

October 2014- 587 pages

- Softcover

- German

ISBN: 978-3-527-33660-9out of print - more