06. August 2015

Geomechanics and Tunnelling 04/15

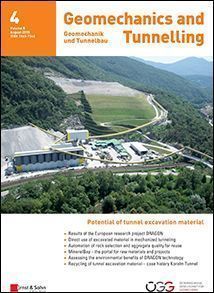

Zum Titelbild: Die Aufbereitung von Ausbruchsmaterial aus maschinellen Vortrieben beinhaltet mehrere Schritte (Vorbrechen, Brechen, Sieben und Korngrößen-Klassifizierung) und findet normalerweise außerhalb des Tunnels statt. Das Titelbild zeigt die Materialbewirtschaftungsanlage in Sigirino, wo das Ausbruchsmaterial aus dem Ceneri Basistunnel aufbereitet wird (s. S. 315). Photo: Alptransit AG

Zum Titelbild: Die Aufbereitung von Ausbruchsmaterial aus maschinellen Vortrieben beinhaltet mehrere Schritte (Vorbrechen, Brechen, Sieben und Korngrößen-Klassifizierung) und findet normalerweise außerhalb des Tunnels statt. Das Titelbild zeigt die Materialbewirtschaftungsanlage in Sigirino, wo das Ausbruchsmaterial aus dem Ceneri Basistunnel aufbereitet wird (s. S. 315). Photo: Alptransit AG

Inhaltsübersicht:

- Results of the European research project DRAGON

- Direct use of excavated material in mechanized tunneling

- Automation of rock selection and aggregate quality for reuse

- MineralBay – the portal for raw materials and projects

- Assessing the environmental benefits of DRAGON technology

- Recycling of tunnel excavation material – case history Koralm Tunnel